production

metalworking

Our metal workshop forms the basis for many of our steel structures. Here, steel profiles and components are cut, machined, and prepared for further manufacturing. Precise drilling, notching, and precise adjustments ensure that all parts fit together perfectly and can be assembled efficiently.

A key focus is the preparation for hot-dip galvanizing. All components are manufactured and assembled to ensure optimal coating and subsequent long-term protection against corrosion. We rely on high-quality, thick-walled raw materials and employ clearly defined processes to guarantee consistent quality, high stability, and a long service life for our products.

welding robots

For recurring welding tasks, we use a welding robot. This results in welds of consistently high quality, with high dimensional accuracy and a clean appearance. The programmed sequences ensure precise control of the welding process and reduce deviations that can occur with manual production.

The welding robot is characterized not only by high precision but also by impressive speed. This optimizes the production process and reduces lead times, especially for series production and standardized assemblies. In this way, we combine robust designs with reliable, reproducible manufacturing quality and create a secure foundation for further processing and assembly.

Hot-dip galvanizing

In hot-dip galvanizing, the prepared steel parts are immersed in a single layer of molten zinc. The component is completely encased, including edges, corners, and hard-to-reach areas. This creates a firmly adhering zinc layer that reliably protects the steel from moisture and environmental influences.

This zinc coating provides the playground equipment with durable and robust corrosion protection. This increases its resistance to outdoor use and ensures a permanently stable and low-maintenance surface.

Powder coating

Since 2012, we have been coating components in our own facility in RAL colors using our large-format powder coating system. Galvanized, electrically conductive steel is powder-coated manually within the system. This manual application allows for precise control of material usage, thus saving powder. This conserves resources and also has a positive impact on costs.

After application, the component is baked in an oven, which hardens the coating and creates a durable surface. Powder coating provides a high-quality appearance, additional surface protection, and long-lasting colorfastness in daily use.

CNC milling machine

Our CNC milling machine is used to mill bases for tower combinations and spring riders from HDPE sheets. Machining is carried out precisely according to CAD data, ensuring that contours and cutouts are implemented with exact dimensions and that the parts are immediately ready for further assembly.

To optimize material utilization, the milling programs are planned to produce as many components as possible from a single sheet. The resulting offcuts are recycled and processed into new PE granules. In this way, we combine efficient manufacturing with the responsible use of resources.

Plasma CNC

For our steel flame-cut parts, we use plasma CNC machining to produce components precisely, reproducibly, and economically. The computer-controlled cutting system works from CAD data, accurately replicating contours, cutouts, slots, and drilling patterns according to the drawing. This ensures consistently high dimensional accuracy.

This process is ideally suited for steel sheets and plates of varying thicknesses. The cut edges are clean and provide a reliable basis for further processing, such as welding or subsequent surface treatments like galvanizing or coating. This results in steel components that can be efficiently assembled and meet our quality requirements in terms of both function and appearance.

Bar machining center - Aluminum

We use a bar machining center to process our aluminum profiles. This allows for precise and repeatable machining of profiles, from cutting and drilling to milling, notching, and assembly preparation. Machining is CNC-controlled according to defined programs, ensuring consistently high dimensional accuracy and fit, even in series production.

Automated processes reduce processing times and minimize potential errors. This results in aluminum components with clean edges, precise connections, and a high surface quality that can be directly integrated into assemblies and provide a reliable basis for further assembly.

Bar machining center - steel

We use a bar machining center to process our steel profiles, ensuring precise and repeatable preparation. This includes square tubes such as 10 x 10 cm as well as round profiles. Depending on the component, cuts, drilling, notches, and other machining operations are carried out exactly according to the drawings, so that the profiles are ready for assembly with a perfect fit.

CNC machining ensures consistently high dimensional accuracy, even for series production and recurring components. At the same time, machining times are reduced and processes are standardized. This results in clean connections, stable joints, and a reliable foundation for subsequent steps such as welding, bolting, or surface treatment.

Rotomoulding

We have owned a rotary melting machine since 2014, which we use to manufacture components such as slides or roofs from polyethylene. The respective mold is attached to the rotating device with a crane, filled with PE granules, and then pushed into the oven, which is heated to around 270 degrees Celsius.

Inside the oven, the mold rotates biaxially, ensuring that the heated granules are evenly distributed along the inner wall, resulting in a homogeneous wall thickness. After controlled cooling, the component is removed from the mold, any imperfections are smoothed, and it is prepared for further processing. This process yields robust, weather-resistant plastic components with consistent quality and a clean surface.

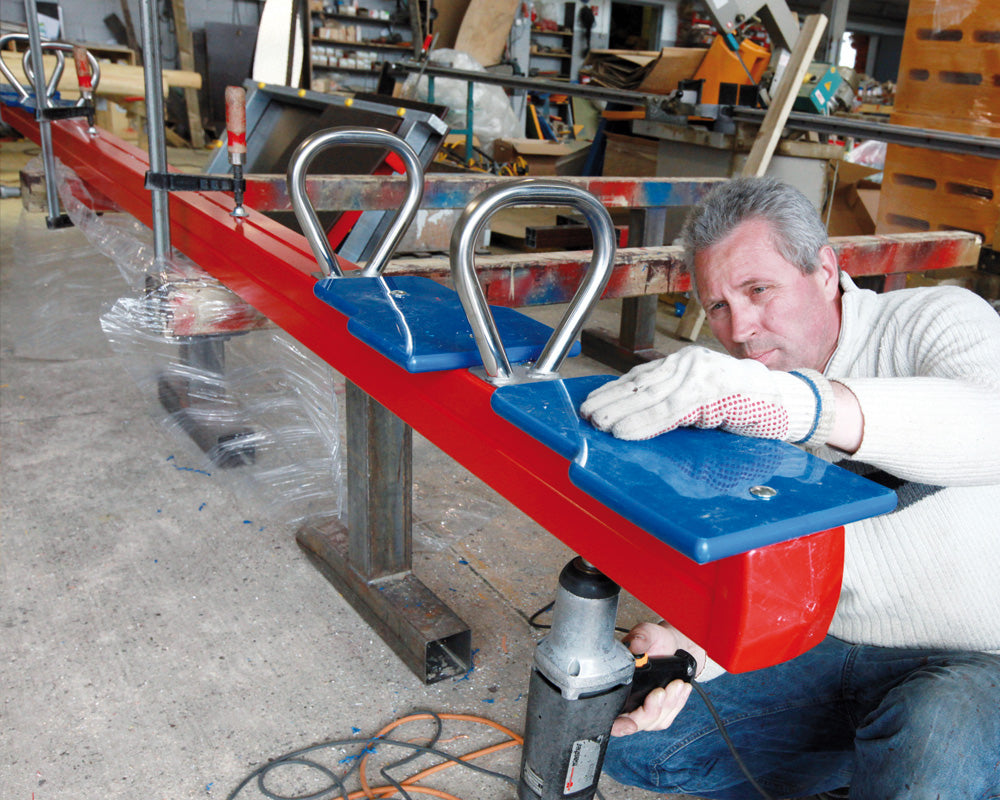

Assembly

In our workshop, all components are carefully assembled by hand into complete playground equipment. We pay close attention to precise connections, clean workmanship, and the reliable function of all components. Well-established processes and experienced staff ensure consistently high assembly quality.

Our playground equipment is mostly delivered pre-assembled and usually only needs to be set up or installed on site. This reduces the workload on the construction site, shortens the assembly time, and makes the project more predictable for you. This saves you time and money and allows you to benefit from a fast, efficient installation.

Preparation for shipping

To make assembly as easy as possible for our customers, we continuously develop our towers and optimize the design during the planning phase. Our goal is to design assemblies that can be largely pre-assembled and then shipped in a near-finished state. We pay close attention to clear interfaces, precise connections, and an assembly-friendly arrangement of all components.

The high degree of pre-assembly significantly reduces on-site workload. Assembly becomes faster, simpler, and easier to plan, saving time on the construction site and making implementation more economical.